perpendicularity measurement|how to measure perpendicularity manually : bulk Learn how to measure perpendicularity using a square ruler, a feeler gauge, or a coordinate measuring machine (CMM). Compare the advantages and disadvantages of different methods and see sample drawings and results. Juju FuracaoWoman, Porn actress, 36y. Subscribe 6.6k. Add to friends.

{plog:ftitle_list}

Resultado da 16 de mar. de 2023 · Vídeo amador nacional com essa Lays Peace fodendo no banheiro da festa com amiguinho. Essa morena gostosa demais ficou .

Learn how to measure perpendicularity using a square ruler, a feeler gauge, or a coordinate measuring machine (CMM). Compare the advantages and disadvantages of different methods and see sample drawings and results.Perpendicularity. The perpendicularity requirement specifies the accuracy of .Perpendicularity is measured using a height gauge, similar to flatness, however, the gauge (or part) is locked to a 90° datum to measure how perpendicular the surface is. The entire surface .Learn what perpendicularity means in geometric dimensioning and tolerancing (GD&T) and how to draw and measure it for planes and axes. Find out the difference between MMC and LMC, .

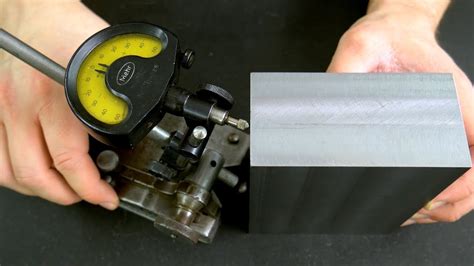

perpendicularity measurement tool

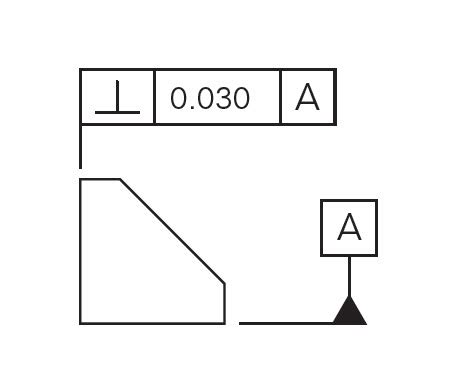

perpendicularity callout on drawing

Learn how to measure perpendicularity, a type of orientation control in GD&T, for surfaces and axes. See the difference between perpendicularity and other callouts such as flatness and angularity.Perpendicularity is used within the context of geometric dimensioning & tolerancing (GD&T) to describe a constraint between two features of a part or assembly which must be at 90° to . There are different methods and tools available to measure perpendicularity, such as master squares, optics, and electronic height gages. Assessing perpendicularity in mechanical systems is essential for proper .

The perpendicularity in GD&T is a tolerance that specifies the degree to which a surface or feature must be perpendicular to a specified datum plane or axis. It indicates how the orientation of a right-angled part feature can .

Perpendicularity. The perpendicularity requirement specifies the accuracy of how perpendicular a target is to the datum (reference plane or line). Instead of degrees, millimeters are used as the unit for the value of perpendicularity .Perpendicularity-Tolerance in GD&T controls the perpendicularity of a surface feature or an axis with respect to the datum plane. It controls the variation in a surface from perfect right angle (90º) w.r.t. to datum plane or surface when .Definition of Perpendicularity. In GD&T, Perpendicularity can refer to either Surface Perpendicularity or Axis Perpendicularity. Surface Perpendicularity is a tolerance that controls Perpendicularity between two surfaces aligned at 90 .

is california driving test hard

measuring perpendicularity with height gauge

is canadian citizenship test hard

Surface Perpendicularity measurement using Square ruler block and surface gauge. Surface perpendicularity measurement using dial gauge. When applied to an Axis. Go and No-go gauges are the best and easiest way to measure .Procedure:. 1. Create a new GD&T Measure from the Measures dialog or the right-click menu.. 2. Assign the new GD&T Measure a Name and Description (if desired).. 3. Select [Add] and select any features from the graphics window or .Basically, measuring the perpendicularity is almost similar to measuring the squareness. Measuring the squareness assesses the 4 sides of the subject to measure while measuring the perpendicularity involves 2 sides only. You .Definition of Perpendicular Lines. In geometry, perpendicular lines are defined as two lines that meet or intersect each other at right angles $(90^{\circ})$.The term ‘perpendicular’ originated from the Latin word ‘perpendicularis,’ meaning a plumb line. If two lines AB and CD are perpendicular, then we can write them as AB $\bot$ CD.

Perpendicular lines are formed when two lines meet each other at the right angle or 90 degrees. This property of lines is said to be perpendicularity.In this article, we are going to discuss what is perpendicular, the properties of perpendicular lines, the difference between perpendicular and parallel lines, and many solved examples in detail.

The perpendicularity control (b) defines how much a surface on a real part may vary from being perpendicular to a specified datum. Tolerance Zone: The perpendicularity tolerance zone (when controlling a surface) is the volume between two parallel planes that .The right angle is considered to be the creation of the human mind, because in nature its presence is not deliberate. In the products of human endeavor, however, whether in architecture, in trades or industry, in civil engineering and even in agricultural activities, the right angle, resulting from the mutual perpendicularity of lines and surfaces, has been present since .Gaging and Measurement of Perpendicularity. Refer to the Tolerance Zone diagrams above and you can tell pretty quickly how to sweep to measure Perpendicularity. For the Surface Perpendicularity example, sweep an indicator along an axis perpendicular to a surface plate that is serving as the datum, for example.

Perpendicularity is an angularity control but this one is set at 90 degrees. It is not strictly angularity though. . The distance of the surface from B cannot exceed it's size tolerance at any point so this provides a measure of orientation control to B. If you want to orient it more tightly to B only but not necessarily A, then you would use . If a straight edge was placed against the bottom of the flagpole, your perpendicularity measurement would be the acceptable distance that the top of the flagpole could deviate from that straight edge. Perpendicularity is done right in this example – no issues found. Perpendicularity Makes Parts ManufacturableThe condition of perpendicularity may be represented graphically using the perpendicular symbol, . Perpendicular intersections can happen between two lines (or two line segments), between a line and a plane, and between two planes. . Other geometric curve fitting methods using perpendicular distance to measure the quality of a fit exist, as .

how to measure perpendicularity manually

The foot is rocked in a small arc when in contact with the part or calibration reference, and the high reading of the indicator sweep is the actual perpendicularity measurement. The instrument is typically set to zero on the right-angle reference, and part perpendicularity is plus or minus some dimension from the true-square zero point.

cost-effective, take your critical measurement challenges in-house on a sub-contract basis. Coordinate Measuring Machines Sensor Systems Vision Measuring Systems Test Equipment and Seismometers . perpendicularity – Straightness, roundness – Flatness, cylindricity – Profile, runout – Etc., etc., etc. 4 Mitutoyo Legex 12128 CMM at U.S .

The PG900-2-1 is a high-precision gage for quick and accurate measurement of hole perpendicularity. The PG900-2-1 gage features accuracy and versatility unsurpassed by any other hand-held gage. The PG900-2-1 is the most advanced hand-held perpendicularity gage. This gage can be used with ease and confidence throughout the entire manufacturing and .

How it works. The 90-Line is placed into the laser beam path and redirects the laser beam off at a precise right angle from the original laser beam. The 90-Line has an internal optical element called a penta-prism that reflects the laser at . Perpendicularity Measurement. When comparing them with other GD&T annotations, both the surface and axis perpendicularity are relatively easy to measure. Surface Perpendicularity Measurement. An . After the machining process is complete, a thorough inspection of the finished product is essential. Machinists should use coordinate measuring machines (CMMs) or other precision measurement tools to verify that the .

It allows both size and orientation to be measured quickly on the line, as opposed to having to measure perpendicularity with a CMM. (Coordinate-Measuring Machine). Axis Controls: Straightness, Axis Angularity, Axis Parallelism, True Position, and Axis Perpendicularity can all be called out to control a center axis. Usually, when this is a case .OVERVIEW The measurements discussed in this chapter primarily concern the digressions from a nominal direction or position of characteristic elements of the inspected surfaces. Learn more about Chapter 11: The Measurement of Straightness, Flatness and Perpendicularity on .

The perpendicularity control (b) defines how much an axis on a real part may vary from being perpendicular to a specified datum. . The axis is located by measuring the surface of the FOS. 3. If the axis is completely contained with the cylindrical tolerance zone, the axis is within specifications. .

is casper test hard

the direct way to measure perpendicularity is to measure the diagonals of a large rectangle from the gantry extremes. Zero difference is square. If you want to use a square, you do it with a dial indicator mounted to the gantry. You run the gantry up and down one axis, adjusting the square so that you get zero change as you move.Orientation tolerance determines the orientation for the form in relation to a reference. This section explains the symbols of three geometrical characteristics, i.e. parallelism, perpendicularity, and angularity, in an easy-to-understand manner, using sample drawing indications. “Learning GD&T From Scratch,” provided by KEYENCE, walks you through the .

The implementation of perpendicularity in manufacturing and measuring is never perfect and is assessed as achieving a greater or lesser degree of perpendicularity. . It should also be pointed out that the perpendicularity measurement is only as good as the reference surface upon which it is based. Since these tend to be surface plate related .

Gauging / Measurement: Surface: A part is constrained and a gage measures along a straight line. In this example, the height variance is measured to see how flat or straight the line is along this surface. . perpendicularity controls the angle at which the pin is to a datum. Both constrain the axis of a pin feature and used gages to control .measuring technology. We can also design, build, test and deliver measuring solutions and even, if deemed cost-effective, take your critical measurement challenges in-house on a sub-contract basis. Coordinate Measuring Machines Sensor Systems Vision Measuring Systems Test Equipment and Seismometers Form Measurement Digital Scale and DRO SystemsDownload scientific diagram | Measurement of perpendicularity deviation of axis to plane: a) a design drawing with characteristic points, b) measurement model Finally, the formula for .

A Polícia Civil do Amazonas (PC-AM), por meio da Delegaci.

perpendicularity measurement|how to measure perpendicularity manually